Play showreel

We are a family business established in 1994 in South Bohemia, Czechia. Our focus is industrial sewing and mounting for automotive, textile & construction industries. Thanks to using a modern technologies is your project in great hands. Our long-term experiences and precision make us a reliable partners for your project's implemetations. We have been holders of ISO 9001 certificate since 2017.

Our services spread out to 4 spheres. We can do things with industrial sewing, we can mount well, we can laser precisely and in the textile industry we are a like fish to water.

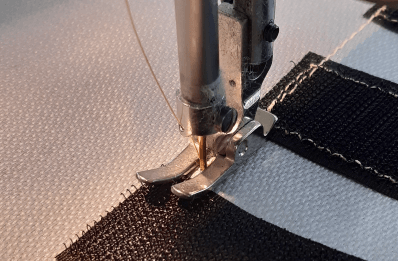

Bracket machine and programmable machines with sewing plane of 100x160 milimetres. Our two experts in the game.

Keening on details and technical maturity has been securing real quality in the thermal cutting with hot knives, soldering irons and ultrasonic cutting for almost 30 years on the market. There are two ways of press we are working with - pneumatic and manual.

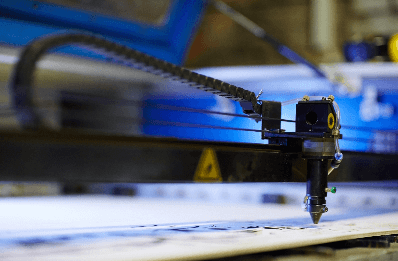

One of the most effective method. We have been dealing with this very well precise since the company establishment. CO2 lasers are used for soft materials cutting like fabrics, plastics or plywood.

Our straight sewing machines with wheel feed are the most relevant kind of slippery materials treatment. We penetrate zig-zag stich and overlock machines in production.

Don't hesitate to contact us! Our pleasure to answer you.

Contact usWe are here for you - that's our job. We do projects tailor-made and our will is to serve you in the best sense of the word. Underneath, we are going to describe you how super easy and effective is an execution of your ideas.

1

First of all, we will check your plans followed by your engineering drawing application.

2

After quotation's approval of ours we will receive your project that launches our work with the machines.

3

Now it's our turn. It starts with the template process following by procedures and finishes with the picking the most valuable machines relevantly to your project's needs.

4

Prototype creation and communication are the most important aspects to make your product perfect at all points.

5

As your satisfaction with the final product reaches the top, we will pack the stuff softly and send it to you over.

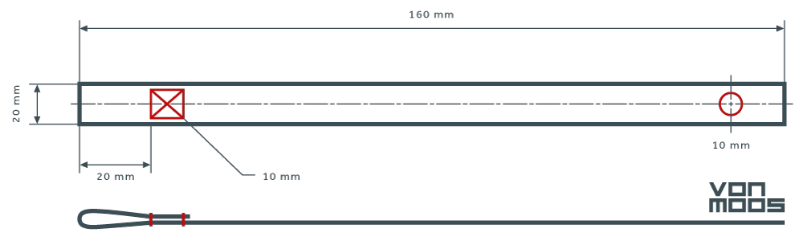

5000 pieces straps for automotive industry - In the engineering drawing you can see the final draft before entering the production process. First step started a laser cut with the tailormade length and diameter opening followed by strap seaming to loop by sgraffito stitch. We keen on being precise so you can be assured that threads are well cleaned. Then we put the finishing touches in it, thoroughly packed by our colleagues not to get even a single damage and that's it. The product is on the way to your house.

Any questions or demands? Send us a message or call us on +420 387 201 946

VON MOOS s.r.o.

Vltavská 1286, Hluboká nad Vltavou, 373 41

CZECH REPUBLIC

VON MOOS s.r.o.

Vltavská 1286, Hluboká nad Vltavou, 373 41

CZECH REPUBLIC

Company owner